We all remember the Spirograph from our childhood. It was that plastic geometric drawing toy where you spun a pen inside plastic gears to create satisfying, looping patterns.

But what if you took that concept, supersized it, and strapped a high-powered industrial router to it?

That is exactly what Cory from Fortress Fine Woodworks did. In a feat of engineering madness, he reinvented an old toy to carve one of the most intricate walnut tables ever made.

Here is the interesting story behind the “Spirograph Table.”

1. Reinventing the Wheel (Literally)

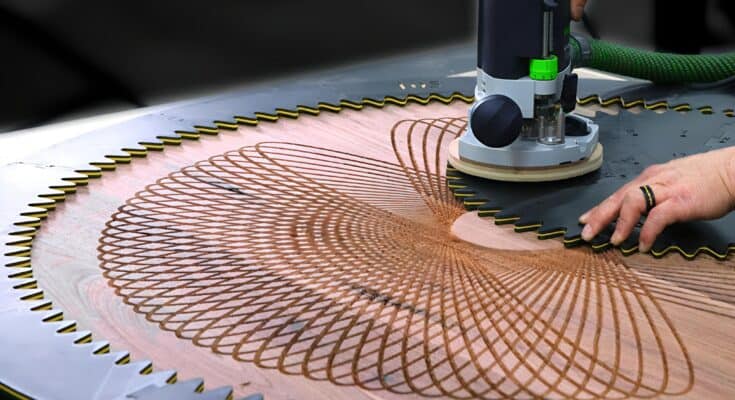

To achieve a perfect, geometric carving pattern on a massive slab of Rustic Walnut, Cory didn’t use a CNC machine (a computer-controlled cutter). Instead, he decided to build a giant, manual Spirograph.

He used a Bambu Lab X1 Carbon 3D printer to print a custom-designed gear system. These weren’t small plastic parts; they were massive, interlocking gears designed with zero tolerance.

- The Setup: A massive outer ring clamped to the table.

- The “Pen”: A heavy woodworking router strapped to the inner gear.

- The Goal: To spin the router around the table 52 times perfectly to carve a deep, hypnotic pattern.

2. The “Hula Hoop” Technique

Before he could even carve the pattern, he had to build the table base. He used a technique he calls “Hula Hooping.”

By creating a hollow center in the stacked wood layers, he could spin the pieces on his joiner (a flattening machine) like a hula hoop. This allowed him to flatten massive 12-foot boards that would normally be impossible to manage, proving that sometimes the weirdest methods work the best.

3. A 7-Hour Workout from Hell

Using a giant Spirograph sounds fun, but in reality, it was a physical nightmare.

Unlike a drawing that takes 30 seconds, carving wood requires force. Cory had to manually push the router through the walnut for 52 separate passes.

- The Effort: He described it as a “full-body workout” where his abs, arms, and back were burning.

- The Duration: It took a staggering 7 hours of continuous, body-shaking labor to finish the pattern.

- The Fear: One slip-up would ruin thousands of dollars of walnut wood instantly.

4. The Fatal Mistake (And the Fix)

halfway through the process, disaster struck. The massive gear system slipped.

Because he hadn’t screwed the jig down tight enough, the pattern shifted. If he continued, the lines would overlap and ruin the symmetry.

In a panic, he had to realign the gears by eye, checking “top dead center” on every single pass. He managed to save it, screwing the system down for the final passes to create a deep, flawless “double line” pattern that looked intentional, even though it started as an accident.

5. The “Gem” Profile

To finish the piece, he gave the table a unique edge profile he calls “The Gem.”

Instead of a standard rounded edge, he cut a massive chamfer (angle) on the underside. This gives the heavy table a floating, jewel-like appearance. After pouring layers of high-gloss epoxy to seal the carving, the result is a piece of furniture that looks like it was made by a machine, but was actually carved by hand using a toy.

Conclusion

This project proves that innovation often comes from looking backward. By taking a simple concept—a plastic drawing toy—and scaling it up with modern 3D printing technology, this woodworker created something a computer could never replicate: a geometric masterpiece built with sweat, gears, and a little bit of madness.

Want to see the visuals? Watch the full deep-dive video below:

Love creative engineering? Check out our Technology category for more inventions, or see our Art & Literature tag for more design stories.

2 Comments on “He Turned a Child’s Toy Into a Giant Machine to Carve This Table”